With this checkweigher model, which combines high-precision weighing and metal detection functions, you can achieve accurate results even for the smallest products. Designed for global standards, this solution is already in use across multiple countries and is ready for export.

With these very sensitive feeders, both the raw material, which is the system input, are saved and the system output is homogeneous, and the plant operates more efficiently.

With this checkweigher model, which consists of a combination of checkweigher and metal detector, you can carry out high-precision weighings for products of the smallest sizes, which are 100% domestically designed, manufactured and assembled.

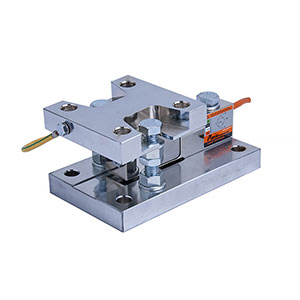

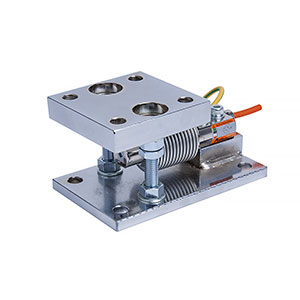

In our gravimetric single screw dosing systems, the entire feeding system is located on a weighing platform. With the operation of the screw feeder, the system is weighed in each unit of time and the amount of decreasing material is calculated. This amount of material is compared with the target value and the engine is commanded for the appropriate speed calculated. With the simultaneous control and correction process, the target value is kept within a sensitive tolerance band.